How can we assist you with your servo press?

If you are looking for a precise, energy-efficient, and reliable solution, servo press technology is an excellent choice. However, lack of careful planning or an unsuitable machine/application can significantly reduce its benefits. Ensure the safety and efficiency of your production with expert support.

Consulting

We assist our clients in selecting the right system, maximizing technological potential, and optimizing processes. From the initial idea to full implementation, we guide you through the world of servo press technology.

Process

01

Assessing production needs and target outcomes.

02

Providing customized recommendations for technology integration, balancing cost and efficiency.

When is it beneficial?

If you do not yet have a clear technological concept. If you want to optimize an existing system.

Implementation

Successful servo press commissioning ensures maximum efficiency and precision. We integrate the system with PLCs and data collection platforms while developing custom programs tailored to specific workpieces and process requirements.

This guarantees optimized production processes and compliance with quality standards.

Implementation Process

01

Analyzing workpiece and process requirements.

02

Creating custom programs and setting parameters.

03

Integrating the servo press with PLC and data collection systems.

04

Testing and fine-tuning for optimal performance.

05

Providing user training and documentation.

When is it beneficial?

- When installing a new servo press.

- When optimizing existing production processes.

- When introducing new manufacturing parameters.

- When integrating with data collection systems.

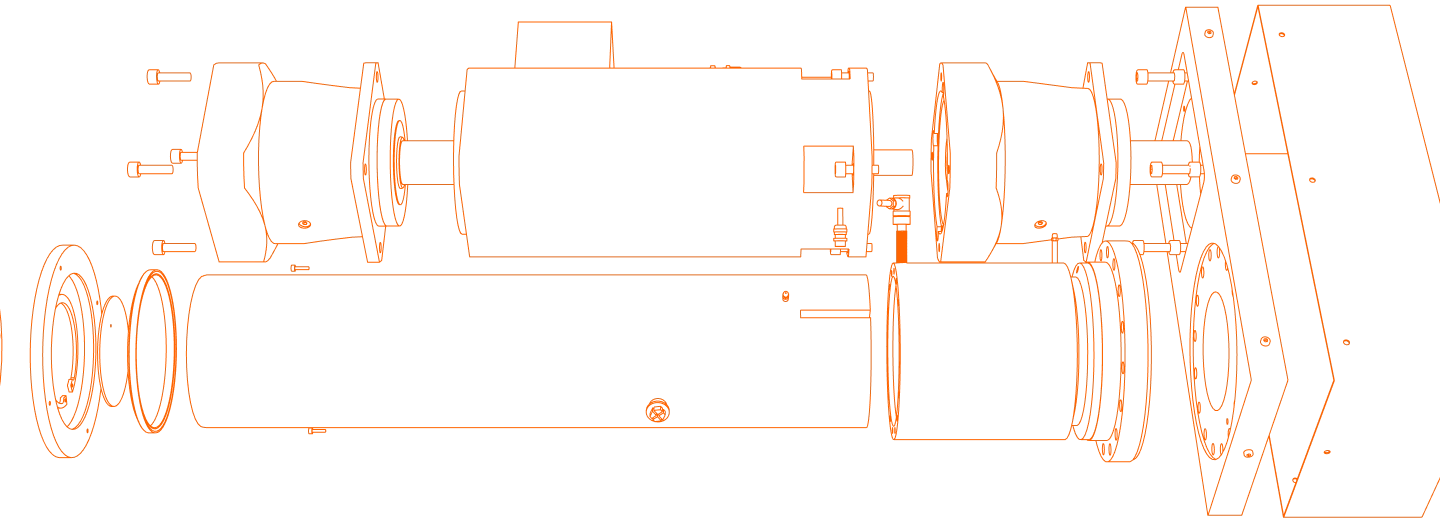

Maintenance & Calibration

To ensure long-term reliability and accuracy, regular maintenance and calibration are essential. We provide detailed calibration documentation, which can be prepared according to international standards as required.

Maintenance & Calibration Process

01

General mechanical and electronic inspection.

02

Lubrication and greasing.

03

Assessing and replacing worn components.

04

Software updates and system optimization.

05

Precision checks and calibration.

06

Preparation of calibration documentation.

When is it beneficial?

- To ensure long service life of the servo press.

- To maintain consistently high manufacturing quality.

- To meet precision requirements.

- To comply with IATF and other industry standards.

Our Technology Partners in the Service of Precision Manufacturing

As the official local representatives of Promess and Kistler, we support precision manufacturing with cutting-edge technologies.

Switching to a servo press can be an excellent decision, but…

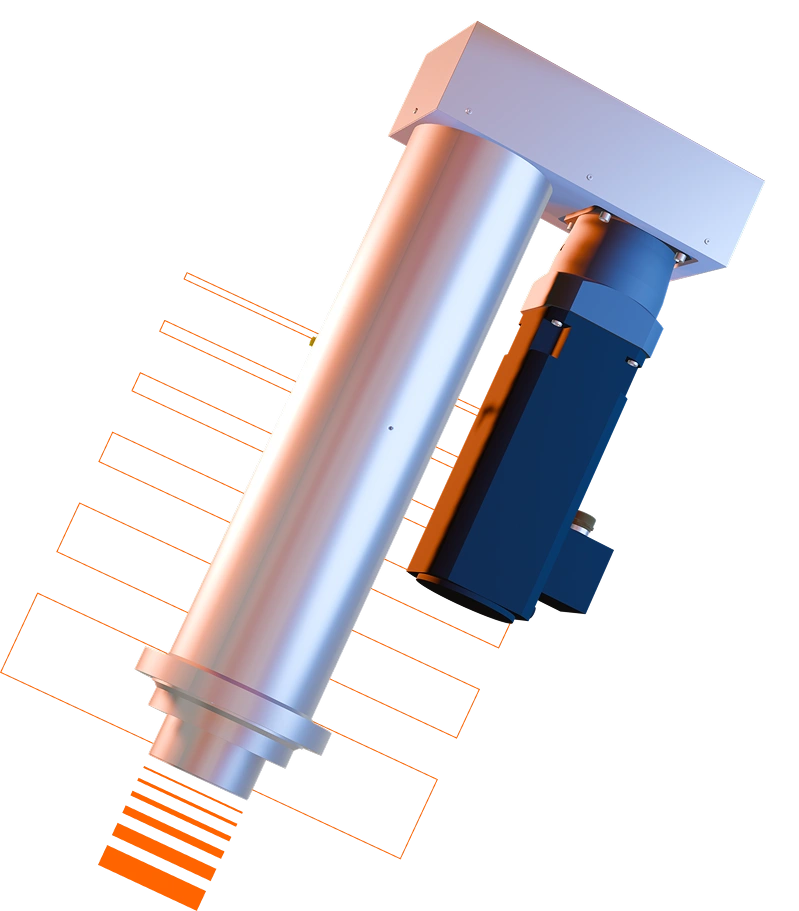

Servo press technology is one of the most advanced assembly solutions today, thanks to its unmatched precision, customizability, and energy efficiency.

However, selecting the right servo press requires expertise and experience, as several factors must be considered, such as the characteristics of the product to be assembled and the manufacturing/assembly requirements. A wrong choice can lead to lower efficiency, breakdowns, and increased scrap rates, whereas a well-chosen machine offers a cost-effective solution in the long run.

Why Work With Us?

We’re Balázs Sarkadi-Nagy and Bálint Varga—engineers with a broad range of expertise, from training and design to quality control and machine servicing.

So why did we decide to specialize in servo presses?

On a practical level, we’ve gained extensive experience in this field over the years, becoming the trusted local partners of several international manufacturers. When servo press issues arise, manufacturers send their clients our way.

From a professional standpoint, we see the transformative potential of this technology in assembly automation—but only if the right tool is chosen for the job. That’s why we support engineering teams and operators at servo press-equipped assembly plants from planning to maintenance.

FAQ

Frequently Asked Questions About Servo Presses

We currently use a hydraulic press. Why should we switch to a servo press?

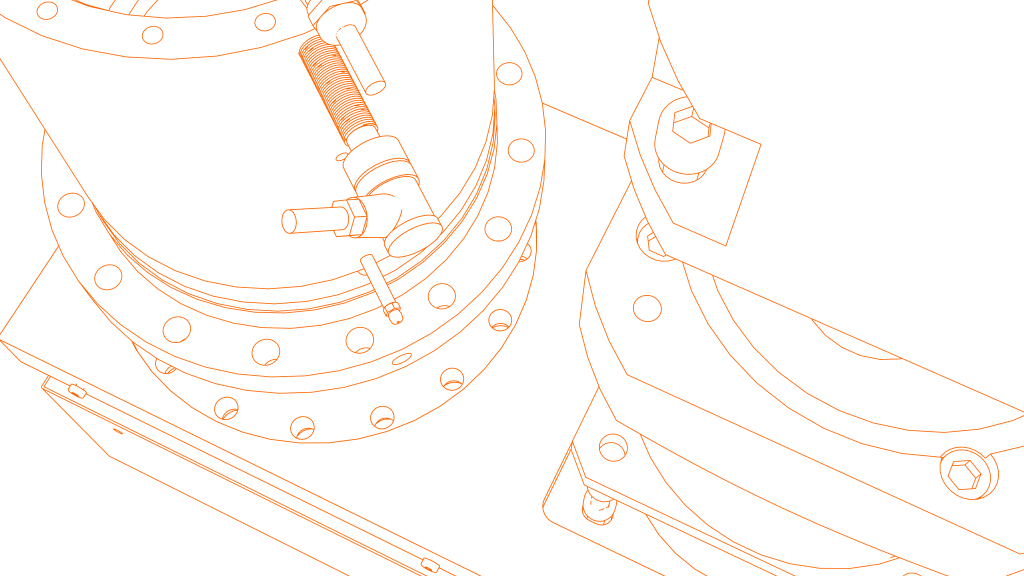

A servo press offers higher precision, flexibility, and energy efficiency compared to hydraulic presses. The servo control system allows for fine-tuned adjustments in force, speed, and displacement, making it ideal for complex or high-precision tasks. Additionally, servo presses are quieter, cleaner, and require less maintenance, as they contain fewer fluid-based components.

How does a servo press improve efficiency?

A servo press optimizes repeatability and energy consumption, making processes faster and more precise. Its ability to continuously monitor and adjust operations reduces the number of defective parts, leading to cost savings and increased productivity. Moreover, its quick reconfiguration and programmable settings provide greater flexibility, especially for changing production requirements.

Servo presses seem like an expensive technology.

- Energy efficiency: Servo presses consume significantly less energy than hydraulic or pneumatic presses, resulting in long-term cost savings.

- Cost variations: The price of a servo press depends on production needs and technical specifications. The most expensive model is not necessarily the best fit. Expert consultation can help determine the ideal machine, preventing unnecessary expenses.

I’m not sure if this is the right choice.

That’s completely understandable. Before implementing a servo press, it is essential to thoroughly assess your production needs and capabilities. Our consulting services help analyze your processes and goals to recommend tailored solutions. An initial consultation can determine whether servo press technology is the right investment for your production.

What factors should be considered when selecting a servo press?

Most modern servo presses support industry-standard communication protocols, including PROFINET, PROFIBUS, EtherCAT, and Modbus.

What maintenance tasks does a servo press require?

- Regular lubrication

- Inspection of bearings, belts, and mechanical components

- Periodic checks of the electrical system and control unit

- Software updates and data logging verification

- Routine calibration to ensure precision